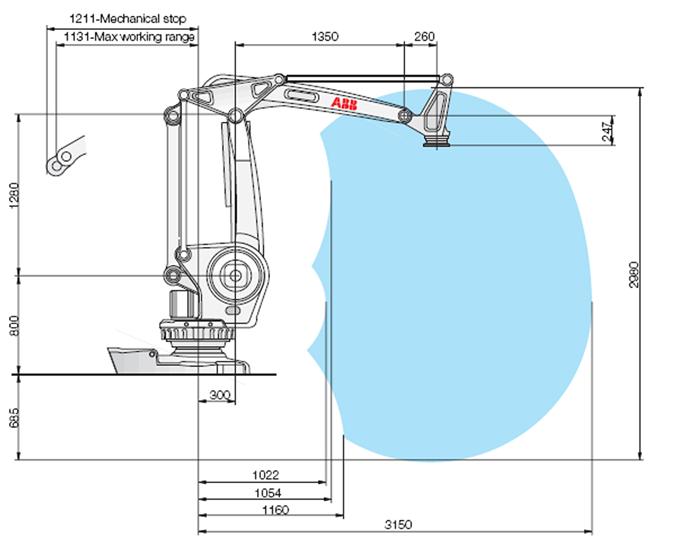

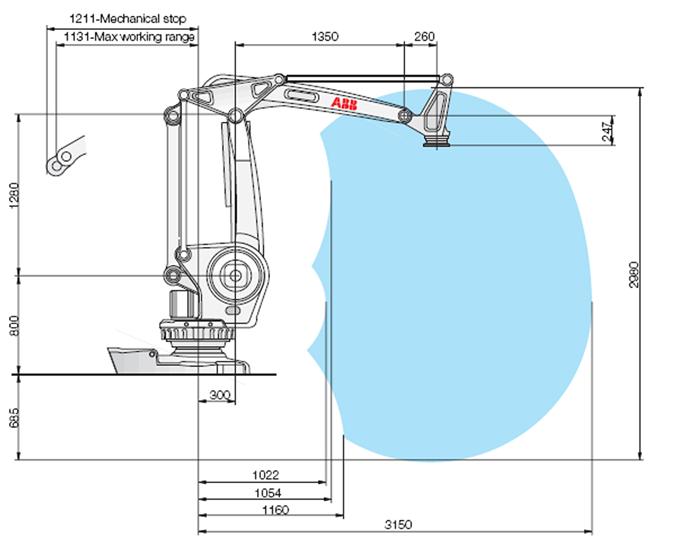

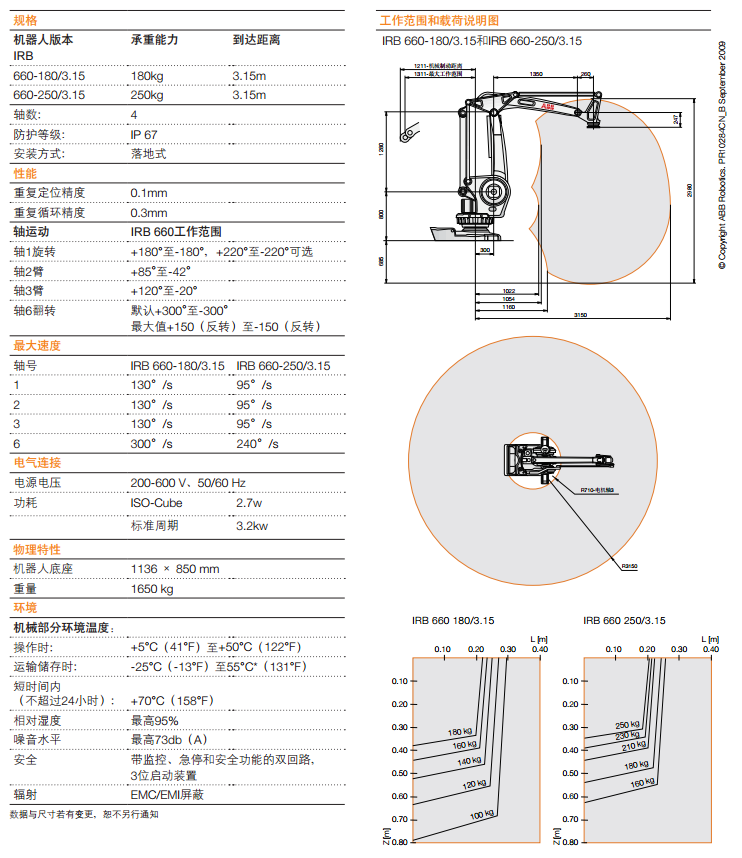

Using the most advanced 4-axis design, it is a high-speed robot with a reach distance of 3.15m and a payload of 250kg. It is very suitable for stacking materials in the form of bags, boxes, crates, bottles and other packaging. In fact, ABB is working to consolidate its position as the only global supplier of fully automated products for packaging line robots.

High reliability-long uptime

The movement speed of IRB 660 robot is significantly higher than that of its predecessor. The optimized motor power and movement performance make it have a shorter cycle time compared with similar products.

Fast speed-short operating cycle time

Use standard packaging software.

High precision-stable production quality of parts

It has extremely high repeat positioning accuracy (± 0.2mm) and track accuracy.

High power-wide range of applications

The high-speed version of the IRB 660 robot has a payload of up to 180kg at full speed, while the high-output 250kg version has a reach of up to 3.15m.

Rugged and durable-suitable for harsh production environments

The robot is sturdy and durable, reaches IP67 protection level, and still has stable performance in the harshest production environment.

Versatility-flexible integration and production

The robot can reach a very long distance, and can be responsible for 4 feeding conveyor belts, 2 pallet stacks, 1 slip pallet stack and 4 stacking discharge lines at the same time. The versatility, reach and load-bearing capacity of the IRB 660 robot can meet almost any palletizing application requirement.